I was researching on line for light modifiers for speed lights and ran across Viewfinder Photography based in England. They sell a kit containing several attachment for speed lights, the kit includes a snoots with grids, a beauty dish with grids & colored gels and a diffusion globe.

The complete kit sells for 139.99 pounds, with today's current exchange rate that equals to $275.00. dollars U.S. That's a bit to much to pay for in my book. I did find just the beauty dish for sale on there web site at a cost of about $175.00 dollars U.S. still to much.

I was digging around the Flickr and found 2 photographers who had build their own beauty dish, Nick Haskins and Tyler Burk. In building my beauty dish, I followed Tyler's design how ever I added a mirror inside of the return.

If you want to make your own beauty dish, follow Tyler's instructions except add a convex mirror inside of the return. I'm including photos here showing more of the process I took in making my beauty dish. This project only took an hour, easy and fun to do.

These are the parts you need to make your beauty dish.

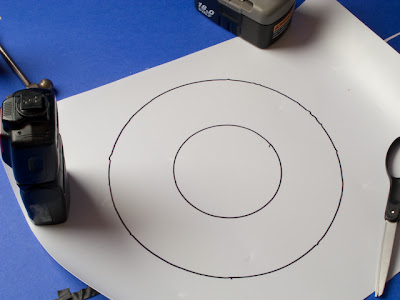

Here I used the gutter part from H.D. to mark my cut.

Here I used the gutter part from H.D. to mark my cut.

Here you are seeing the CD case as it will appear in the dish prior to cutting a hole in it.

Here I am aligning the gutter devise on the back of the CD case to mark where I need to cut my opening for the strobe head. I should caution you on the cutting of the openings on your dish, I used a utility knife which worked very well. As you know, sometime those things can get away from you-be careful.

Here I am aligning the gutter devise on the back of the CD case to mark where I need to cut my opening for the strobe head. I should caution you on the cutting of the openings on your dish, I used a utility knife which worked very well. As you know, sometime those things can get away from you-be careful.

I drilled a hole in the corner of my markings in order to start my actual cuttings, you may not need to do this.

In the above photos you can see the hole in the bottom of the bowl has been cut out and the gutter devise is pushed through in order to check fit.

In the above photos you can see the hole in the bottom of the bowl has been cut out and the gutter devise is pushed through in order to check fit.

This is a view of the face of the beauty dish with gutter devise and than the cut CD case over the top of the gutter thing. In the photos below you can see the fasteners in place, I used the holes in the gutter thing as a guide for drilling holes through the bowl and CD case.

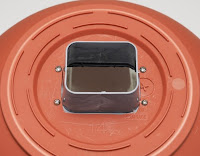

The photo below show the inside of the CD case, the end which the strobe fires into. I glued a CD to the inside/top of the case and than put a convex mirror on top of that. It was my thought that the mirror would help to disperse the light more evenly. I pick up the 3 1/2 inch mirror at a local auto supply store for $2.39.

The photo below show the inside of the CD case, the end which the strobe fires into. I glued a CD to the inside/top of the case and than put a convex mirror on top of that. It was my thought that the mirror would help to disperse the light more evenly. I pick up the 3 1/2 inch mirror at a local auto supply store for $2.39.

The image below shows you what the dish looks like finished and painted. I have also attached additional images of the light for your review.

The image below shows you what the dish looks like finished and painted. I have also attached additional images of the light for your review.

This was a fast and easy DIY project, it took no time at all.

Some additional information regarding dish light: It seems I lose about a stop and a half of light. I am also attaching the photos below so you can see the velco strap around the back of the flash head.

Here are two photos to compare the light quality using the dish. The first is of Ian with bare flash and the second using the beauty dish.

Here are two photos to compare the light quality using the dish. The first is of Ian with bare flash and the second using the beauty dish.